Benefits of Feed Conveyor Chains for the Poultry Industry:

1.Even Feed Distribution: Chain feeding systems ensure that feed is delivered consistently and evenly throughout the feeding line. This reduces competition between flocks, ensures that all flocks receive the same quality and quantity of feed, and promotes flock uniformity in size and weight.

2.Reduced Feed Waste: Chain feeders are often designed with built-in mixing wheels and large-capacity troughs, which help minimize feed spillage and waste, thereby improving feed conversion and reducing operating costs.

3.High Conveying Capacity: These chains can convey large amounts of feed, reducing feeding frequency and ensuring a constant supply of feed.

4.Various Feed Types: Chain conveyor systems are able to easily handle a wide range of poultry feed types, including mash, pellets, and crumbles.

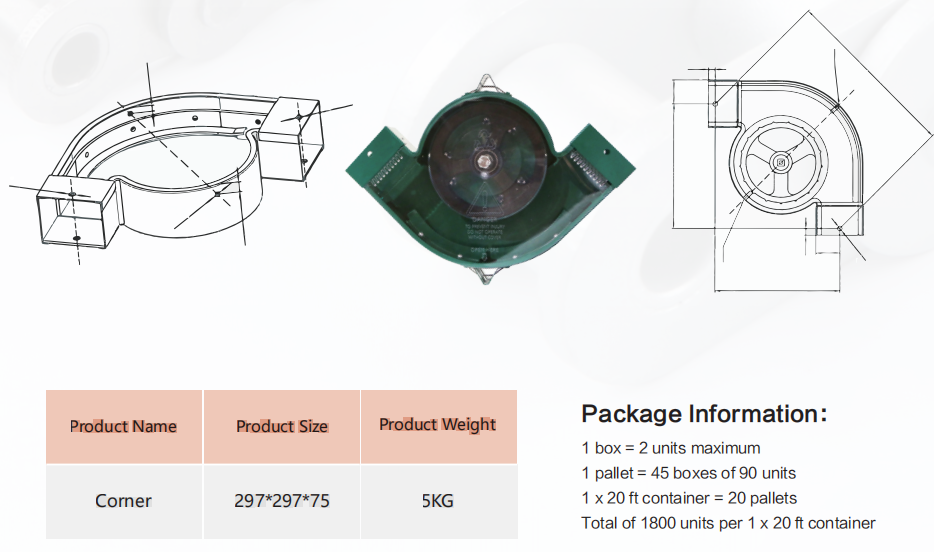

5.Durable and Reliable: Made from high-quality steel, often with advanced surface treatments for corrosion resistance, these chains are designed to ensure long-term durability and reliable performance in the harsh poultry environment. Their corner components are also carefully designed for durability.

6.More space to feed: Chain feeders offer more space to feed than some other feeding methods, allowing birds to feed from both sides of the trough, which reduces stress.

7.Labor savings: Automated chain feeding systems significantly reduce the manual labor required for feeding, allowing staff to focus on other important tasks and improving overall farm efficiency.

8.Improved animal welfare: These systems help improve the health and welfare of birds by reducing competition for feed, ensuring balanced nutrition, and allowing birds to feed in a less stressful environment.

9.Adaptability: Modern chain feeding systems often offer variable speed control, allowing farmers to adjust feed delivery speeds based on the age and needs of the flock. They can also be adjusted for different bird sizes and types (broilers, layers, breeders).

10.Easy installation and maintenance: Many systems are designed to be relatively easy to install and provide quick access for cleaning, inspection, and replacement of parts, minimizing downtime.

1BJY-324 4000LBS Capacity New Condition 12v Motor Trailer Electric Jack Parts and Accessories

1BJY-324 4000LBS Capacity New Condition 12v Motor Trailer Electric Jack Parts and Accessories 1BJY-HM-30 Chrome Ball Multi-Ball Mount New Condition Trailer Parts and Accessories with Clevis Hook Capacity 5000lbs

1BJY-HM-30 Chrome Ball Multi-Ball Mount New Condition Trailer Parts and Accessories with Clevis Hook Capacity 5000lbs 1BJY-A05 New Australian Coupler Equipped 3500KG Capacity Trailer Parts and Accessories with 50mm Ball Size

1BJY-A05 New Australian Coupler Equipped 3500KG Capacity Trailer Parts and Accessories with 50mm Ball Size Customized 40 Short Pitch Stainless Steel Extended Pin Roller Chain and Sprockets for Restaurant Industries

Customized 40 Short Pitch Stainless Steel Extended Pin Roller Chain and Sprockets for Restaurant Industries XG-4 High Quality Customized Rotary Tiller Blade Agricultural Machinery Part for Rotary Tiller Machine

XG-4 High Quality Customized Rotary Tiller Blade Agricultural Machinery Part for Rotary Tiller Machine 1BJY-TJ-15 New Weld-On Pipe-Mount Trailer Jack 5000LBS Capacity with Parts and Accessories Featuring Swivel Feature

1BJY-TJ-15 New Weld-On Pipe-Mount Trailer Jack 5000LBS Capacity with Parts and Accessories Featuring Swivel Feature