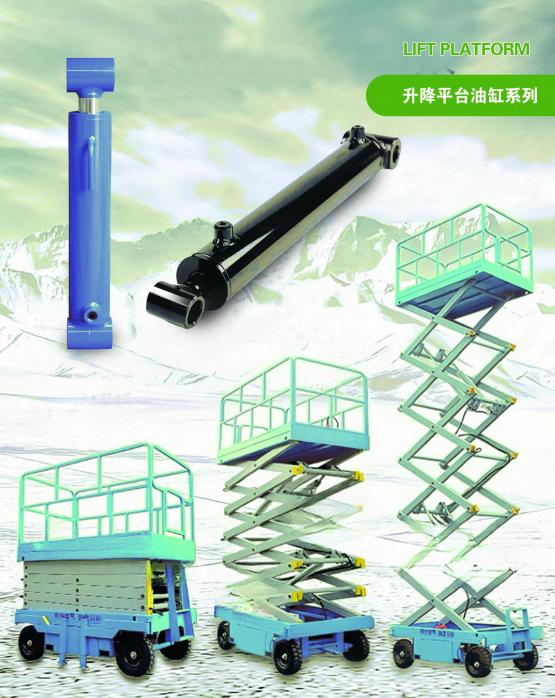

Scissor Lifts:

Function: This is the most common application. One or more double-acting cylinders are mounted horizontally between the scissor legs. When the cylinders extend, they push the scissor legs apart, lifting the platform vertically.

Applications: Warehousing and logistics (order picking, inventory replenishment), manufacturing (assembly line operations, maintenance access), and construction (material handling, temporary work platforms).

Loading Docks:

Function: Cylinders raise and lower the lip of the loading dock and typically power the entire ramp, creating a safe and level bridge between the loading dock and the truck trailer.

Applications: Shipping and receiving platforms in warehouses, distribution centers, and manufacturing plants.

Car Lifts:

Function: Multiple synchronized cylinders (usually telescopic) are used to lift entire vehicles for undercarriage inspection, maintenance, and repair.

Applications: Auto repair shops, tire shops, and fleet maintenance facilities.

Aerial Work Platforms (AWPs) and Boom Lifts:

Function: Boom lifts primarily use cylinders for articulation and extension, while scissor lifts rely solely on lift cylinders to raise the work basket.

Applications: Construction, building maintenance (window cleaning, electrical work), telecommunications installation, and any task requiring safe access at height.

Truck Tail Lifts:

Function: One or more cylinders drive the platform to lift cargo from the ground into the bed of a truck or van.

Applications: Delivery services (especially heavy items), moving companies, utility trucks, and ambulances (for loading stretchers).

Specialized Industrial Lift Tables:

Function: Used to position workpieces at an ergonomic height for operators, lift heavy objects to machine feed height, or as part of automated production lines.

Applications: Assembly stations, packaging lines, metalworking, and printing industries.

1BJY-324 4000LBS Capacity New Condition 12v Motor Trailer Electric Jack Parts and Accessories

1BJY-324 4000LBS Capacity New Condition 12v Motor Trailer Electric Jack Parts and Accessories 1BJY-HM-30 Chrome Ball Multi-Ball Mount New Condition Trailer Parts and Accessories with Clevis Hook Capacity 5000lbs

1BJY-HM-30 Chrome Ball Multi-Ball Mount New Condition Trailer Parts and Accessories with Clevis Hook Capacity 5000lbs 1BJY-A05 New Australian Coupler Equipped 3500KG Capacity Trailer Parts and Accessories with 50mm Ball Size

1BJY-A05 New Australian Coupler Equipped 3500KG Capacity Trailer Parts and Accessories with 50mm Ball Size Customized 40 Short Pitch Stainless Steel Extended Pin Roller Chain and Sprockets for Restaurant Industries

Customized 40 Short Pitch Stainless Steel Extended Pin Roller Chain and Sprockets for Restaurant Industries XG-4 High Quality Customized Rotary Tiller Blade Agricultural Machinery Part for Rotary Tiller Machine

XG-4 High Quality Customized Rotary Tiller Blade Agricultural Machinery Part for Rotary Tiller Machine 1BJY-TJ-15 New Weld-On Pipe-Mount Trailer Jack 5000LBS Capacity with Parts and Accessories Featuring Swivel Feature

1BJY-TJ-15 New Weld-On Pipe-Mount Trailer Jack 5000LBS Capacity with Parts and Accessories Featuring Swivel Feature