Belt conveyor,RTO,Vacuum Pump,Machining Center,hydraulic cylinder,Motor,Agricultural parts,Air compressor,PTO shaft,Gear,V-belt pulley,Timing pulley,Coupling,Chains,Sprocket,Agricultural gearbox,Gearbox/gear reducer,Ungrouped

Spec | Factor K1 |

DC01, DCL01 | 5.2 |

DC02, DCL02 | 4.7 |

DC03, DCL03 | 4.1 |

DC35, DCL35 | 3.7 |

DC04, DCL04 | 3.4 |

DC05, DCL05 | 3 |

DC55, DCL55 | 2.8 |

DC06, DCL06 | 2.6 |

DC07, DCL07 | 2.4 |

DC08, DCL08 | 2.2 |

DC09, DCL09 | 2 |

DC10, DCL10 | 1.8 |

Working Grade | Working Complexion Factor K2 |

M2 | 1 |

M3 | 1.12 |

M4 | 1.25 |

M5 | 1.4 |

M6 | 1.6 |

M7 | 1.8 |

M8 | 2 |

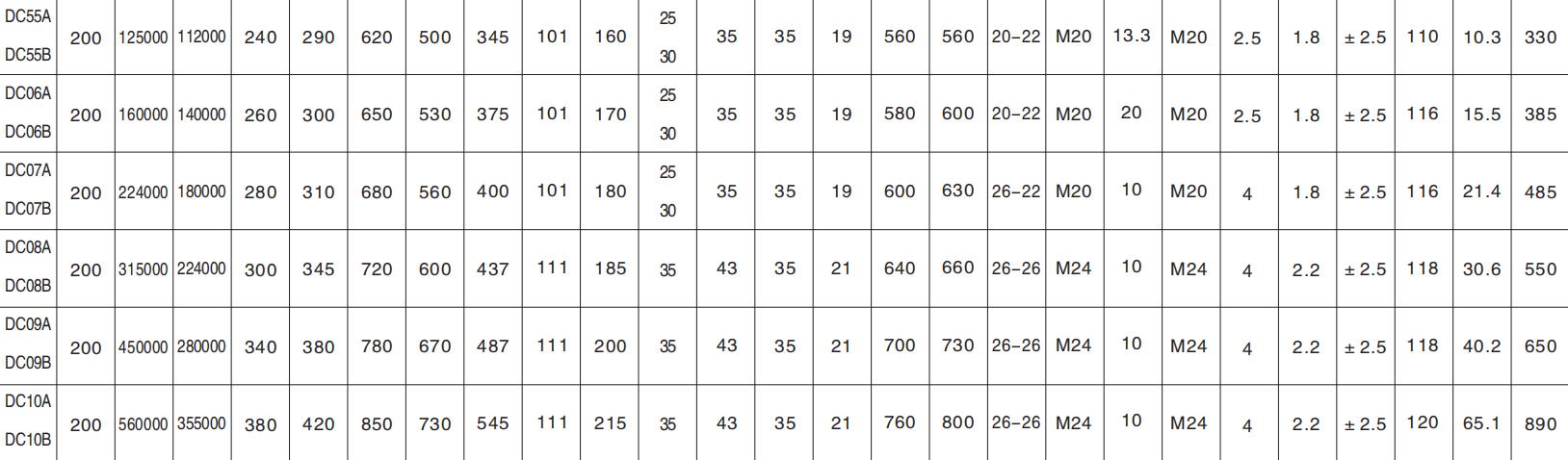

Flange sizes connection mode between drum and coupling |

connecting flange size |

Type | H (mm) | C1 (mm) | S(F8) (mm) | D1 (mm) | D2(F8) (mm) | α (°) | N-d1 (mm) |

DC01A, DC01B | ≥20 | 4 | 360 | 360 | 280 | 30 | 10-18 / 10-M16 |

DC02A, DC02B | ≥20 | 4 | 380 | 380 | 310 | 30 | 10-18 / 10-M16 |

DC03A, DC03B | ≥20 | 4 | 400 | 400 | 340 | 30 | 10-22 / 10-M20 |

DC35A, DC35B | ≥25 | 4 | 460 | 460 | 400 | 20 | 10-22 / 10-M20 |

DC04A, DC04B | ≥25 | 4 | 500 | 500 | 420 | 20 | 14-22 / 14-M20 |

DC05A, DC05B | ≥30 | 5 | 530 | 530 | 450 | 20 | 14-22 / 14-M20 |

DC55A, DC55B | ≥30 | 5 | 560 | 560 | 500 | 13.3 | 20-22 / 20-M20 |

DC06A, DC06B | ≥30 | 5 | 580 | 600 | 530 | 13.3 | 20-22 / 20-M20 |

DC65A, DC65B | ≥30 | 5 | 590 | 615 | 545 | 13.3 | 26-22 / 26-M20 |

DC07A, DC07B | ≥30 | 5 | 600 | 630 | 560 | 10 | 26-22 / 26-M20 |

DC08A, DC08B | ≥45 | 5 | 640 | 660 | 600 | 10 | 26-22 / 26-M20 |

DC09A, DC09B | ≥45 | 5 | 700 | 730 | 670 | 10 | 26-26 / 26-M24 |

DC10A, DC10B | ≥45 | 5 | 760 | 800 | 730 | 10 | 26-26 / 26-M24 |

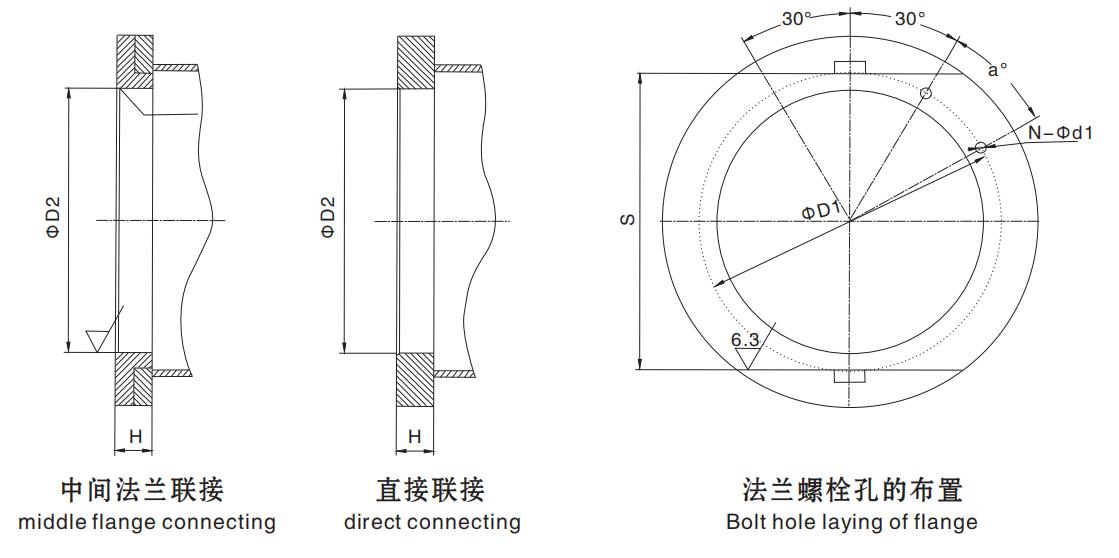

connecting flange size |

Type | H (mm) | L (mm) | C1 (mm) | S(F8) (mm) | D1 (mm) | D2(F8) (mm) | α (°) | N-d1 (mm) |

DC01A | ≥25 | ≥10 | 4 | 360 | 360 | 280 | 30 | 10-18 / 10-M16 |

DC02A | ≥25 | ≥10 | 4 | 380 | 380 | 310 | 30 | 10-18 / 10-M16 |

DC03A | ≥25 | ≥10 | 4 | 400 | 400 | 340 | 30 | 10-22 / 10-M20 |

DC35A | ≥30 | ≥15 | 4 | 460 | 460 | 400 | 20 | 10-22 / 10-M20 |

DC04A | ≥30 | ≥15 | 4 | 500 | 500 | 420 | 20 | 14-22 / 14-M20 |

DC05A | ≥40 | ≥20 | 5 | 530 | 530 | 450 | 20 | 14-22 / 14-M20 |

DC55A | ≥50 | ≥25 | 5 | 560 | 560 | 500 | 13.3 | 20-22 / 20-M20 |

DC06A | ≥50 | ≥25 | 5 | 580 | 600 | 530 | 13.3 | 20-22 / 20-M20 |

DC65A | ≥50 | ≥25 | 5 | 590 | 615 | 545 | 13.3 | 26-22 / 26-M20 |

DC07A | ≥50 | ≥25 | 5 | 600 | 630 | 560 | 10 | 26-22 / 26-M20 |

DC08A | ≥60 | ≥35 | 5 | 640 | 660 | 600 | 10 | 26-22 / 26-M20 |

DC09A | ≥60 | ≥35 | 5 | 700 | 730 | 670 | 10 | 26-26 / 26-M24 |

DC10A | ≥60 | ≥35 | 5 | 760 | 800 | 730 | 10 | 26-26 / 26-M24 |

Screw Specification | Anticipated Torque (N·m) |

M8 | 26 |

M10 | 51 |

M12 | 89 |

M16 | 215 |

M20 | 420 |

M24 | 725 |

FOR MORE DETAIL, PLEASE CONTACT US. |

1BJY-324 4000LBS Capacity New Condition 12v Motor Trailer Electric Jack Parts and Accessories

1BJY-324 4000LBS Capacity New Condition 12v Motor Trailer Electric Jack Parts and Accessories 1BJY-HM-30 Chrome Ball Multi-Ball Mount New Condition Trailer Parts and Accessories with Clevis Hook Capacity 5000lbs

1BJY-HM-30 Chrome Ball Multi-Ball Mount New Condition Trailer Parts and Accessories with Clevis Hook Capacity 5000lbs 1BJY-A05 New Australian Coupler Equipped 3500KG Capacity Trailer Parts and Accessories with 50mm Ball Size

1BJY-A05 New Australian Coupler Equipped 3500KG Capacity Trailer Parts and Accessories with 50mm Ball Size Customized 40 Short Pitch Stainless Steel Extended Pin Roller Chain and Sprockets for Restaurant Industries

Customized 40 Short Pitch Stainless Steel Extended Pin Roller Chain and Sprockets for Restaurant Industries XG-4 High Quality Customized Rotary Tiller Blade Agricultural Machinery Part for Rotary Tiller Machine

XG-4 High Quality Customized Rotary Tiller Blade Agricultural Machinery Part for Rotary Tiller Machine 1BJY-TJ-15 New Weld-On Pipe-Mount Trailer Jack 5000LBS Capacity with Parts and Accessories Featuring Swivel Feature

1BJY-TJ-15 New Weld-On Pipe-Mount Trailer Jack 5000LBS Capacity with Parts and Accessories Featuring Swivel Feature