Applications

1. Hydraulic Excavators and Electric Shovels

These are the workhorses of surface mining. Every major motion is driven by large-bore, heavy-duty hydraulic cylinders.

Boom, arm, and bucket cylinders: These three groups of cylinders work together to control digging and lifting movements. They provide the powerful force needed to break rock, scoop up tons of material, and lift it out of the excavation site.

Quick-coupler cylinders: Smaller cylinders that allow the operator to quickly change attachments, such as switching from a bucket to a hydraulic hammer.

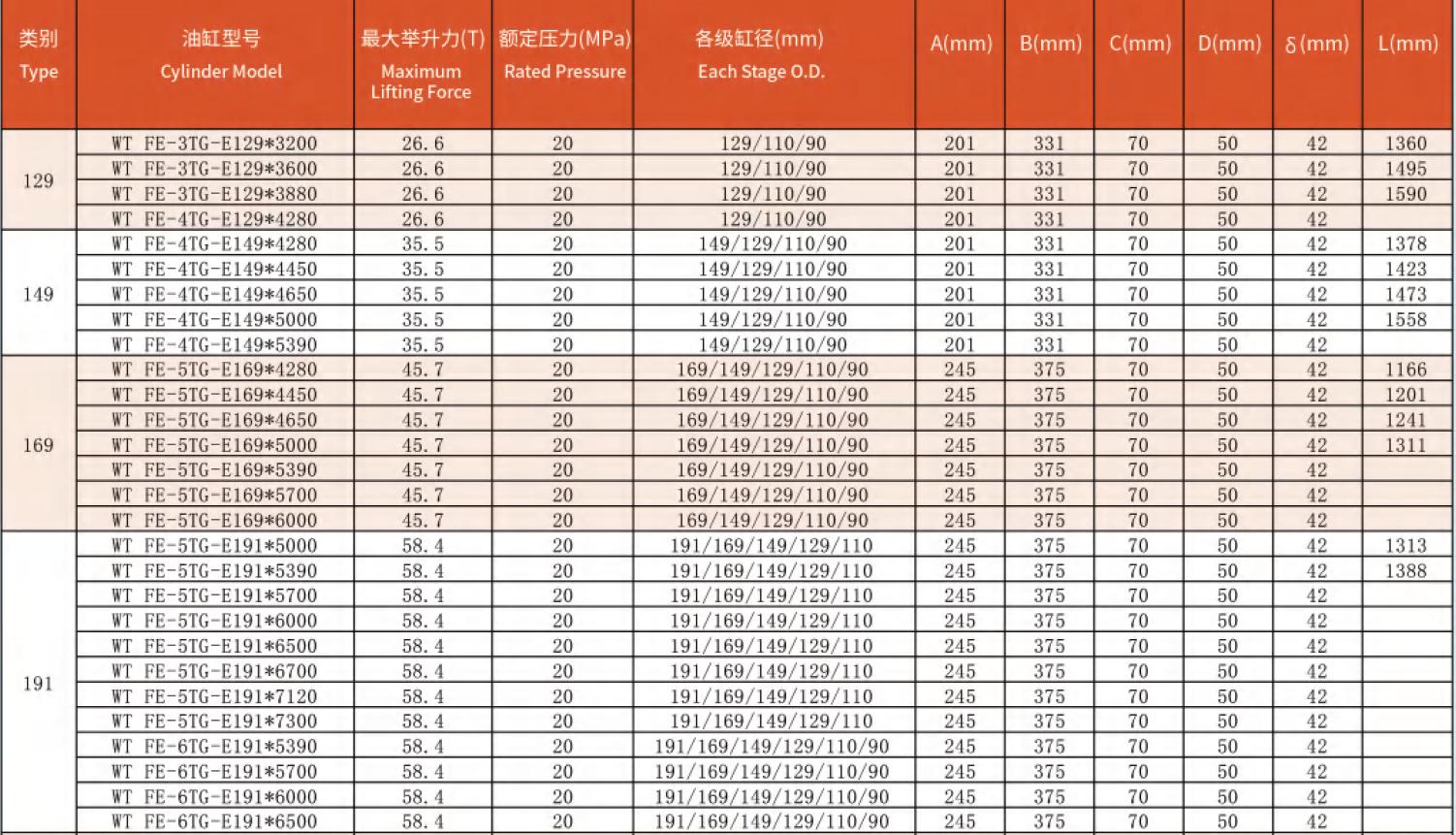

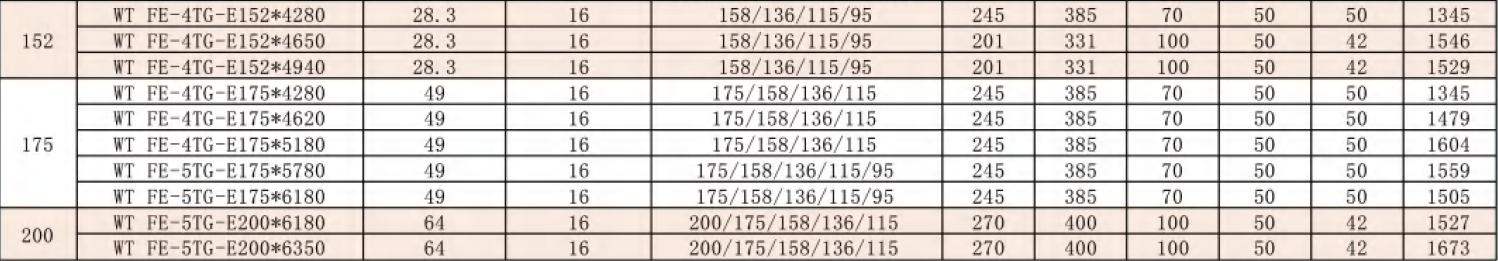

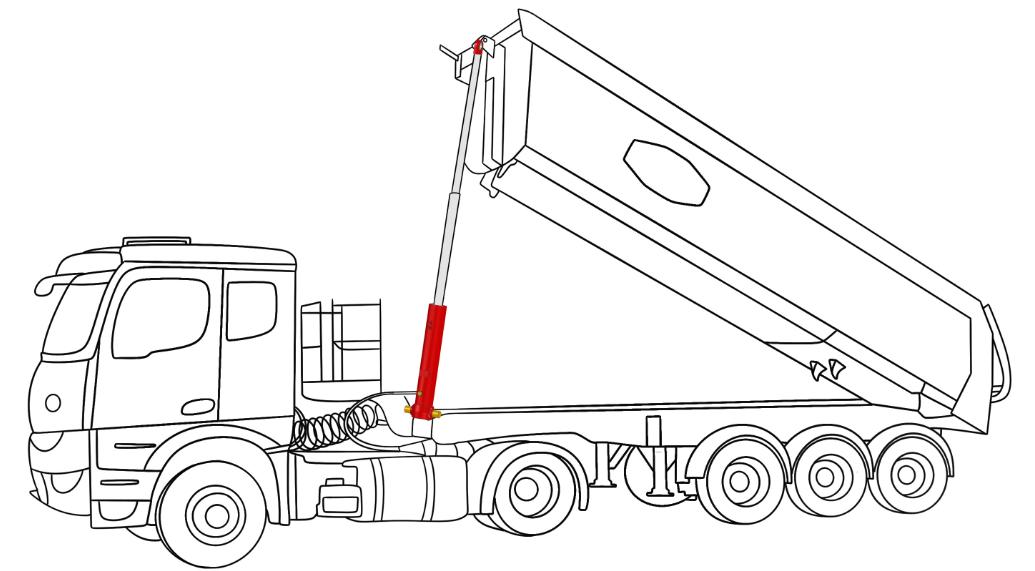

2. Dump Trucks

Dump trucks are the primary tool for transporting materials within the mine. Their most critical hydraulic component is the dump cylinder.

Lift Cylinders: These are typically large, multi-stage telescopic cylinders. When activated, they extend to raise the massive dump bucket, allowing tons of ore or overburden to be quickly and efficiently unloaded to a crusher or scrap yard.

Suspension Cylinders: Many large dump trucks use a hydraulic suspension system (hydro-pneumatic struts), which acts as both shock absorbers and structural support, providing a stable ride even under extreme loads.

Steering Cylinders: Provide steering power to the truck's large front wheels.

3. Bulldozers

Bulldozers are used to clear, level, and move soil.

Blade Lift Cylinders: Two large cylinders on each side of the bulldozer raise and lower the main blade.

Blade Tilt/Angle Cylinders: One or two cylinders tilt the blade forward and backward or left and right, allowing for precise material control and leveling.

Ripper Cylinders: Large cylinders at the rear of the bulldozer control the ripper, a claw-like device used to break up hard ground or rock.

4. Wheel Loaders

Wheel loaders are essential for loading dump trucks and transporting materials around the worksite.

Lift Arm Cylinders: These cylinders raise and lower the main loading arm, which lifts the bucket from the ground to the height of the dump truck. Bucket Tilt Cylinder: Controls the bucket's tilting or "curling" motion, which is crucial for efficient scooping and accurate dumping.

5. Drill Rig

Drill rigs are used to drill holes to accommodate explosives.

Drill Rod and Feed Cylinder: Cylinders are used to lift and position the drill rod. The long-stroke "feed cylinder" provides downward force (pull-down force) to the drill string, forcing the drill bit into the rock.

Leveling Jack: Hydraulic cylinders act as jacks, stabilizing and leveling the entire drill rig on uneven ground, ensuring accurate and safe drilling operations.

6. Underground Mining Equipment

In underground mines, specialized hydraulic equipment is crucial to safety and production.

Longwall Roof Supports: These are massive, shield-like structures lined with powerful hydraulic cylinders (supports). They hold down the mine roof, preventing it from collapsing during coal or ore extraction, and propel the mining equipment forward.

Crusher/Hydraulic Hammer: These attachments are typically mounted on excavators or specialized transport vehicles and use hydraulic cylinders to drive a powerful impact mechanism to break up oversized rock.

1BJY-324 4000LBS Capacity New Condition 12v Motor Trailer Electric Jack Parts and Accessories

1BJY-324 4000LBS Capacity New Condition 12v Motor Trailer Electric Jack Parts and Accessories 1BJY-HM-30 Chrome Ball Multi-Ball Mount New Condition Trailer Parts and Accessories with Clevis Hook Capacity 5000lbs

1BJY-HM-30 Chrome Ball Multi-Ball Mount New Condition Trailer Parts and Accessories with Clevis Hook Capacity 5000lbs 1BJY-A05 New Australian Coupler Equipped 3500KG Capacity Trailer Parts and Accessories with 50mm Ball Size

1BJY-A05 New Australian Coupler Equipped 3500KG Capacity Trailer Parts and Accessories with 50mm Ball Size Customized 40 Short Pitch Stainless Steel Extended Pin Roller Chain and Sprockets for Restaurant Industries

Customized 40 Short Pitch Stainless Steel Extended Pin Roller Chain and Sprockets for Restaurant Industries XG-4 High Quality Customized Rotary Tiller Blade Agricultural Machinery Part for Rotary Tiller Machine

XG-4 High Quality Customized Rotary Tiller Blade Agricultural Machinery Part for Rotary Tiller Machine 1BJY-TJ-15 New Weld-On Pipe-Mount Trailer Jack 5000LBS Capacity with Parts and Accessories Featuring Swivel Feature

1BJY-TJ-15 New Weld-On Pipe-Mount Trailer Jack 5000LBS Capacity with Parts and Accessories Featuring Swivel Feature