Production process of turbine screw elevator

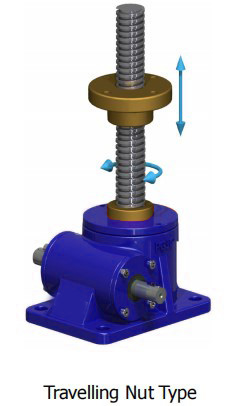

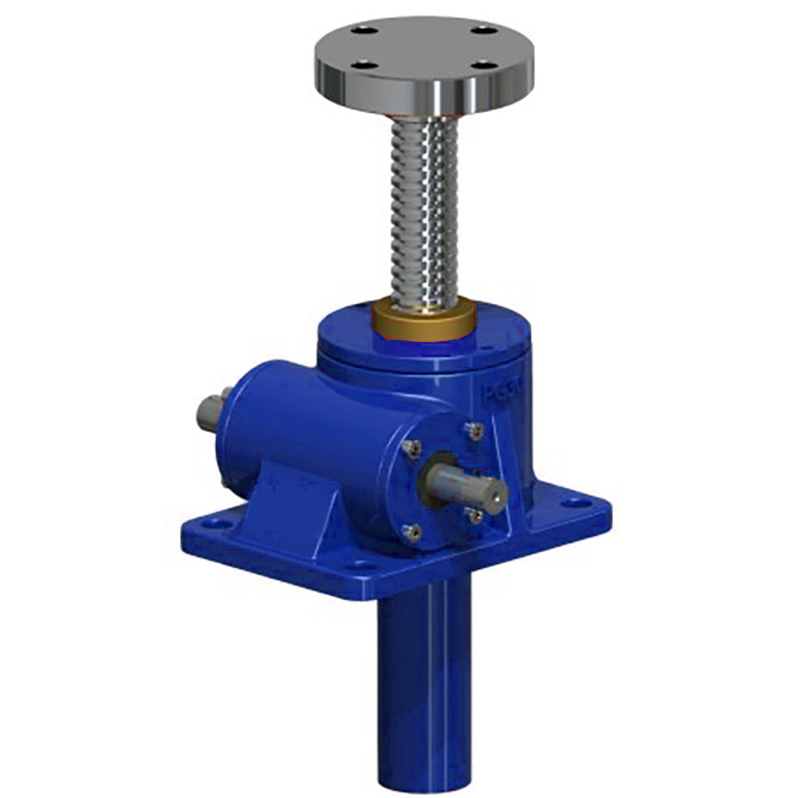

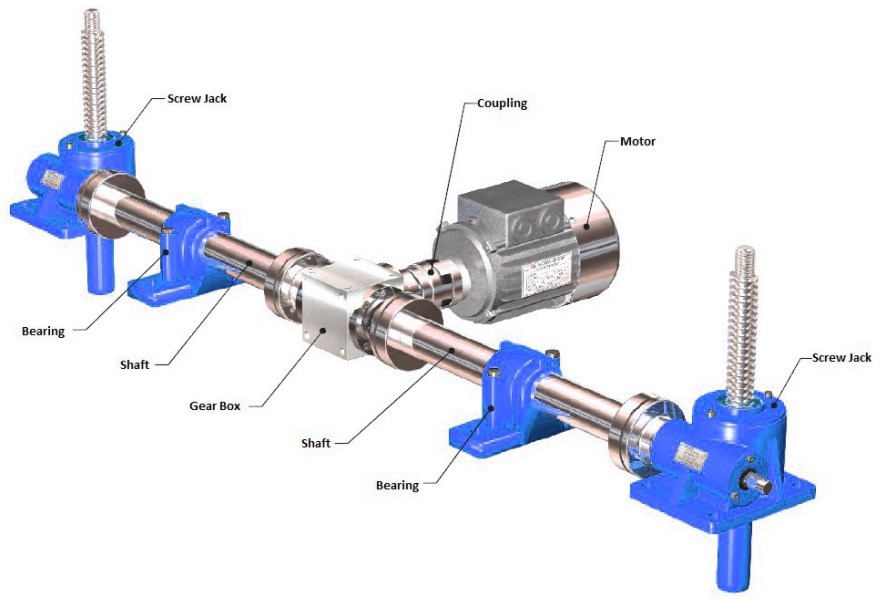

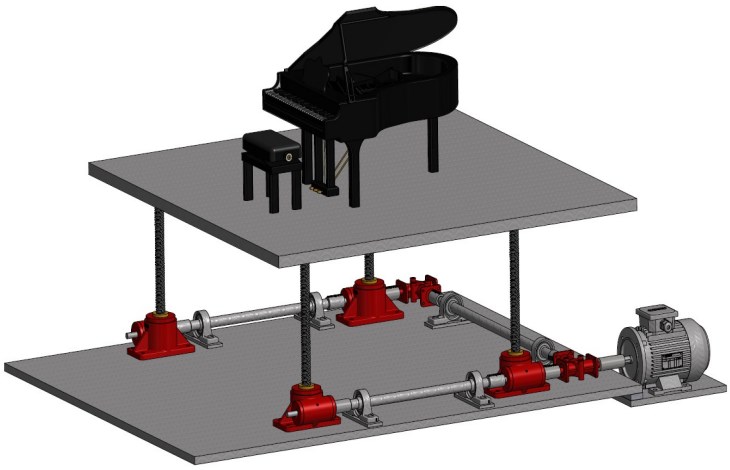

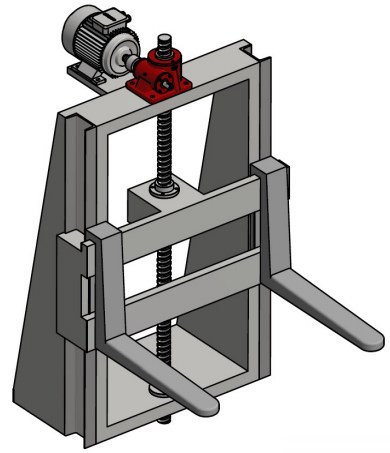

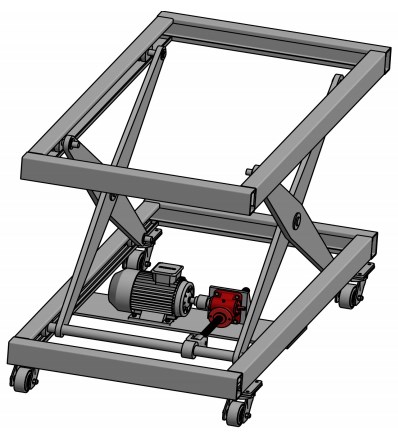

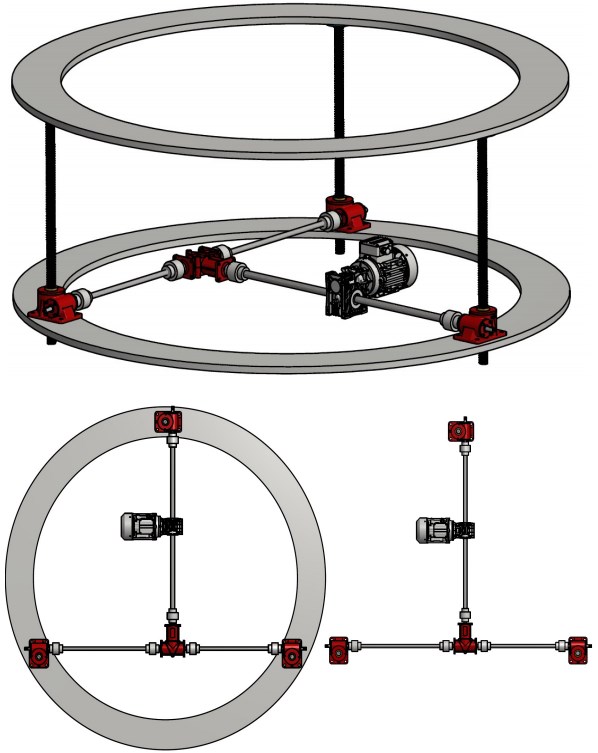

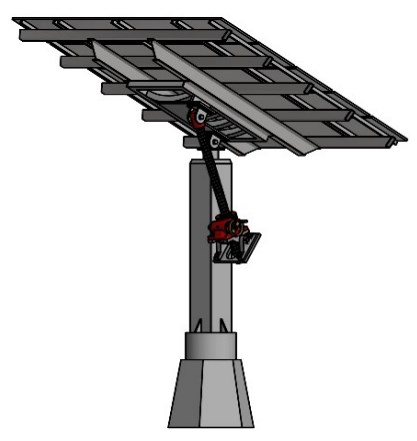

Design: according to the user's needs and requirements, design a special turbine screw lift scheme, including the design of turbine, screw, nut, support structure, control system, etc.

Material preparation: according to the design requirements, prepare corresponding materials, such as turbine, screw rod, nut, platform, etc., and the materials shall comply with relevant national standards and requirements.

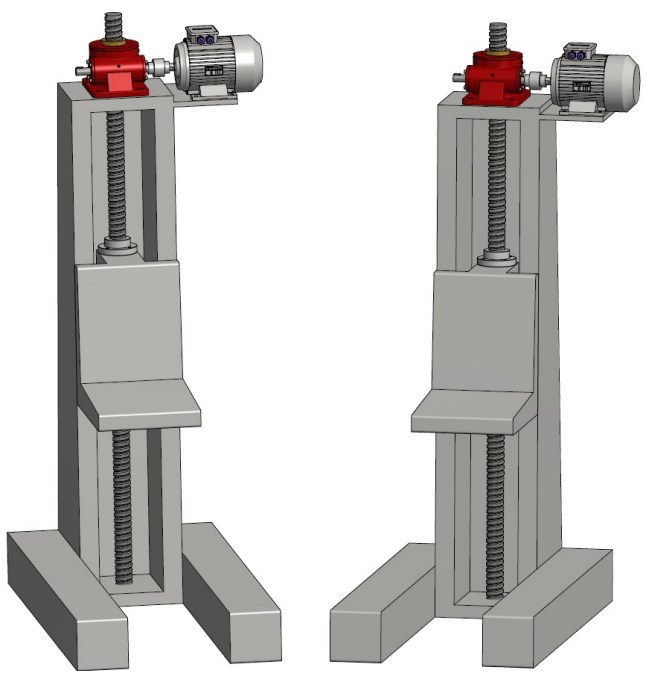

Turbine manufacturing: generally, turbine materials are made of high-quality cast iron, steel and other specially processed materials, which are processed and shaped by CNC processing equipment.

Manufacturing screw rod and nut: according to the design requirements, the screw rod and nut shall be manufactured, and the surface polishing and heat treatment shall be carried out.

Platform processing and manufacturing: according to the design drawings, select the corresponding materials and shapes, and carry out shearing, welding, polishing and other processes.

System assembly: assemble the manufactured turbine, screw rod, nut, platform and other components, and install the control system for testing and quality inspection.

Commissioning and acceptance: The equipment shall be commissioned and accepted by professional personnel to ensure that the equipment meets the design requirements and meets the safety and quality standards.

Delivery and installation: packaging and logistics delivery shall be carried out for the accepted equipment, and installation and commissioning shall be carried out at the customer's site to ensure the normal operation of the turbine screw lift.

In short, design, material preparation, manufacturing and assembly are all crucial to the production process of the turbine screw lift. Any problem in any link will seriously affect the performance and quality of the turbine screw lift produced.

1BJY-324 4000LBS Capacity New Condition 12v Motor Trailer Electric Jack Parts and Accessories

1BJY-324 4000LBS Capacity New Condition 12v Motor Trailer Electric Jack Parts and Accessories 1BJY-HM-30 Chrome Ball Multi-Ball Mount New Condition Trailer Parts and Accessories with Clevis Hook Capacity 5000lbs

1BJY-HM-30 Chrome Ball Multi-Ball Mount New Condition Trailer Parts and Accessories with Clevis Hook Capacity 5000lbs 1BJY-A05 New Australian Coupler Equipped 3500KG Capacity Trailer Parts and Accessories with 50mm Ball Size

1BJY-A05 New Australian Coupler Equipped 3500KG Capacity Trailer Parts and Accessories with 50mm Ball Size Customized 40 Short Pitch Stainless Steel Extended Pin Roller Chain and Sprockets for Restaurant Industries

Customized 40 Short Pitch Stainless Steel Extended Pin Roller Chain and Sprockets for Restaurant Industries XG-4 High Quality Customized Rotary Tiller Blade Agricultural Machinery Part for Rotary Tiller Machine

XG-4 High Quality Customized Rotary Tiller Blade Agricultural Machinery Part for Rotary Tiller Machine 1BJY-TJ-15 New Weld-On Pipe-Mount Trailer Jack 5000LBS Capacity with Parts and Accessories Featuring Swivel Feature

1BJY-TJ-15 New Weld-On Pipe-Mount Trailer Jack 5000LBS Capacity with Parts and Accessories Featuring Swivel Feature