Heavy-Duty Sweep Drives

If you are in the market for heavy-duty slew drives, you are likely wondering what the differences are. Some slewing drives are standard, while others are designed with special features.

Ever power manufactures heavy-duty slewing drives

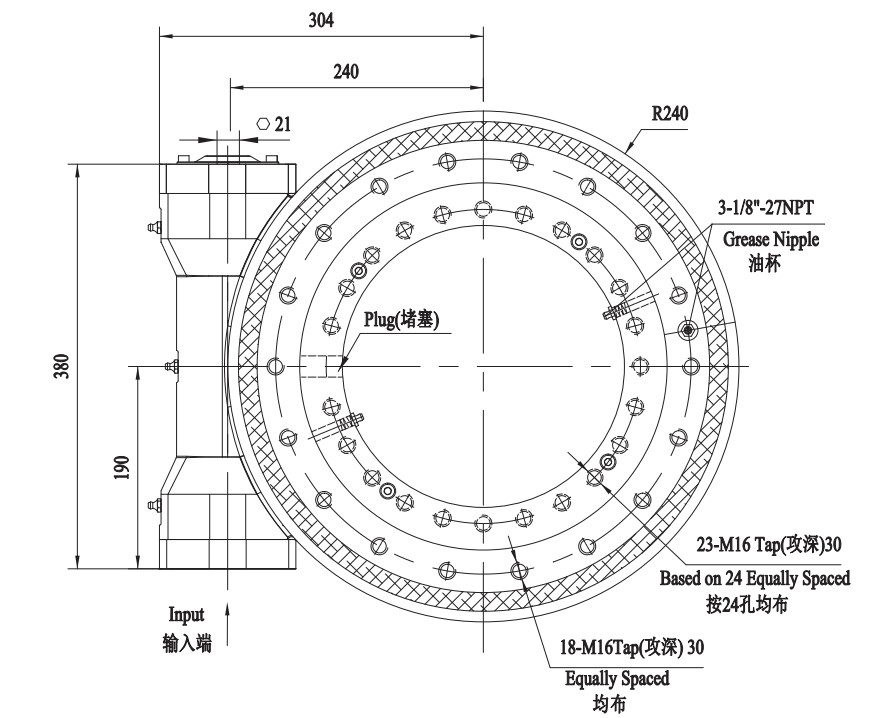

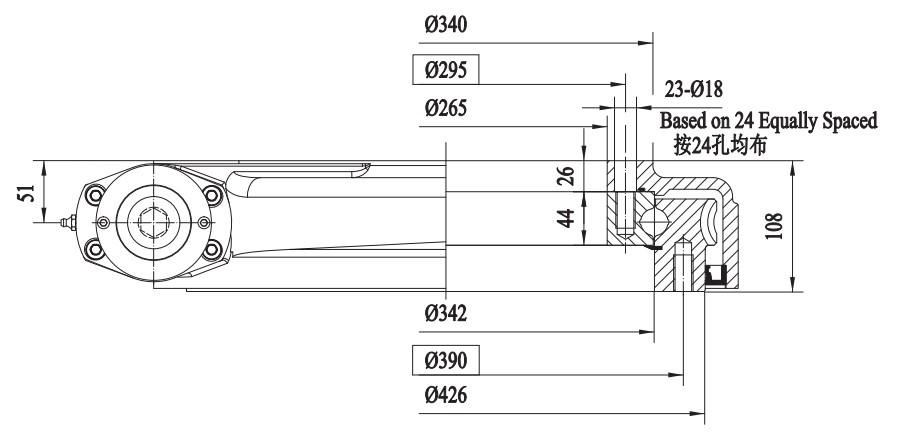

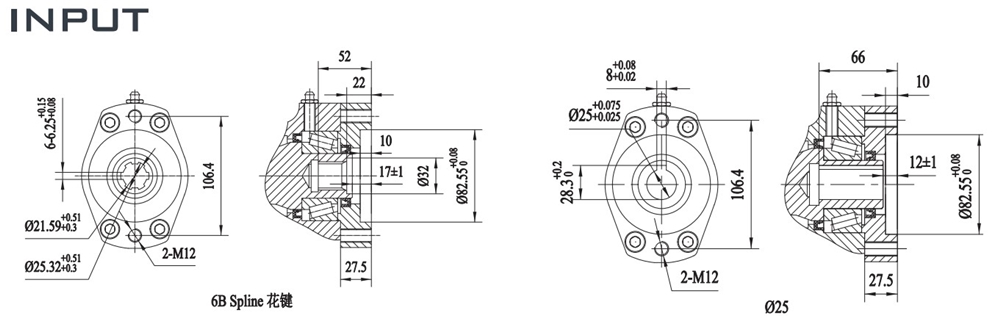

A slewing drive is a gear that turns a rotating shaft or axle. It is often comprised of a slewing ring, worm shaft, housing, and motor. They are commonly used in aerial platforms. These drives are designed for axial, radial, and tilting moments. The advantages of slewing drives include easy installation, easy maintenance, and compact size.

Slewing drives have a long history. Their development might have started as early as ancient Greece with the invention of the endless screw. They were also common in the Renaissance, but the technology used to create them has advanced considerably. Today's heavy-duty slewing drives are made of more complex materials and can perform more sophisticated tasks, but their primary function hasn't changed much.

Slewing drives are used in industrial applications to move industrial machinery. These gearless units deliver high-precision positioning and require minimal maintenance. They are used in industrial machinery and manufacturing plants and can be found in robotics and construction equipment. A robotic arm is a mechanical device that bends and moves in one direction. It is controlled by an electric motor and can be programmed to perform different tasks, such as lifting heavy objects. Its accuracy and versatility have made it a standard component of many types of heavy-duty slewing drives.

Slewing rings come in two forms: plastic and ball bearing-based. The former is more suited for horizontal applications while the latter is better suited to vertical applications. Both slewing rings contain gears to assist movement. They are designed to be durable and reliable in a variety of applications. These drives provide high torque and precision, making them the preferred choice for a wide range of industries.

Ever power slewing drive has better anti-fatigue and bonding ability

Wea slewing drives are characterized by their curved tooth structure, which improves the anti-fatigue and bonding abilities. This series of slewing drives is ideal for medium-speed and low-speed applications. Its full sealed design, better anti-fatigue properties, and reduced weight make it a popular choice for heavy-duty applications. Ever power slewing bearing co.,lt., has been making slewing drives for over 30 years and continues to improve its products.

Ever power slewing drives are the most versatile slewing drive options, featuring a variety of designs for a variety of applications. They can be used on wind turbines, digger derricks, fog cars, and other industrial machinery. The slewing drive is also available in enclosed designs to reduce the risk of workplace injuries. The Ever power slewing drive has a higher anti-fatigue and bonding ability than traditional drives, which can cause fatigue or a loss of performance.

FWA slewing drive

Compared to other slewing drives, the FWA series is designed to handle heavier loads and have higher carrying capacities. These slewing drives feature an enclosed design and have two or more worms. They are highly durable and require little space for installation. They are often used in applications like mining, agriculture, and manlift platforms. They are also used in a wide range of maritime applications.

This slew drive is available in a variety of standard series or can be customized to meet your specific needs. Various configurations are available, including ones suitable for high temperatures or for use in extreme environments. For optimum performance, consider the mounting structure and application. Ever power's engineers can help you design a slew drive that will meet your needs.

1BJY-324 4000LBS Capacity New Condition 12v Motor Trailer Electric Jack Parts and Accessories

1BJY-324 4000LBS Capacity New Condition 12v Motor Trailer Electric Jack Parts and Accessories 1BJY-HM-30 Chrome Ball Multi-Ball Mount New Condition Trailer Parts and Accessories with Clevis Hook Capacity 5000lbs

1BJY-HM-30 Chrome Ball Multi-Ball Mount New Condition Trailer Parts and Accessories with Clevis Hook Capacity 5000lbs 1BJY-A05 New Australian Coupler Equipped 3500KG Capacity Trailer Parts and Accessories with 50mm Ball Size

1BJY-A05 New Australian Coupler Equipped 3500KG Capacity Trailer Parts and Accessories with 50mm Ball Size Customized 40 Short Pitch Stainless Steel Extended Pin Roller Chain and Sprockets for Restaurant Industries

Customized 40 Short Pitch Stainless Steel Extended Pin Roller Chain and Sprockets for Restaurant Industries XG-4 High Quality Customized Rotary Tiller Blade Agricultural Machinery Part for Rotary Tiller Machine

XG-4 High Quality Customized Rotary Tiller Blade Agricultural Machinery Part for Rotary Tiller Machine 1BJY-TJ-15 New Weld-On Pipe-Mount Trailer Jack 5000LBS Capacity with Parts and Accessories Featuring Swivel Feature

1BJY-TJ-15 New Weld-On Pipe-Mount Trailer Jack 5000LBS Capacity with Parts and Accessories Featuring Swivel Feature