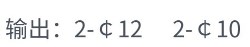

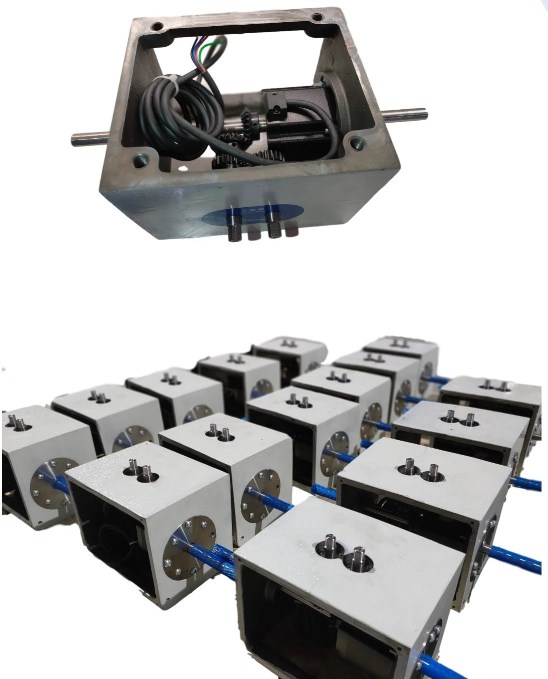

Non-standard gearboxes have significant applications in both the textile equipment and chemical industry, facilitating various processes and functions. Here are some specific applications of non-standard gearboxes in these industries:

Textile Equipment:

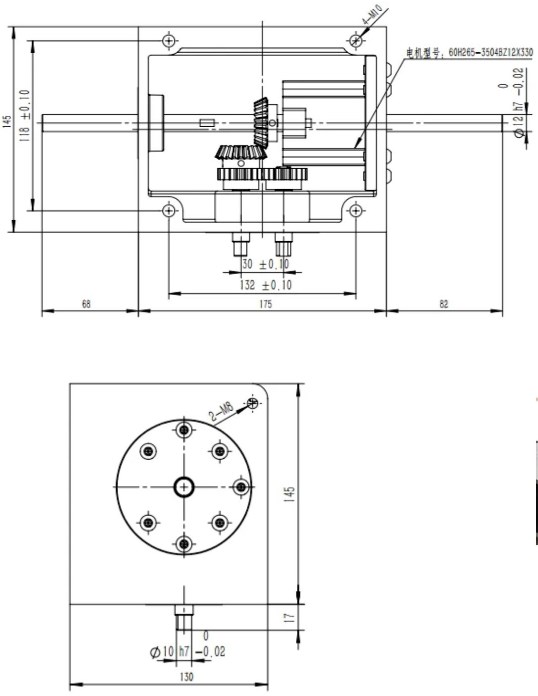

1. Spinning Machines: Non-standard gearboxes are used in spinning machines, such as ring spinning machines and open-end rotor spinning machines. These gearboxes drive the rotating components, including the spindles, bobbins, and drafting systems. They provide precise speed control, twist adjustment, and tension control, ensuring the production of high-quality yarns.

2. Weaving Machines: Non-standard gearboxes find applications in weaving machines, such as rapier looms, air-jet looms, and projectile looms. These gearboxes drive the shedding mechanisms, picking systems, and take-up rollers. They enable precise control over the weaving speed, fabric tension, and pattern synchronization, resulting in accurate and uniform fabric production.

3. Knitting Machines: Non-standard gearboxes are employed in knitting machines, including circular knitting machines and flat knitting machines. These gearboxes drive the needle beds, carriage movements, and stitch selection mechanisms. They provide controlled and synchronized motion, allowing for precise knitting patterns and fabric structures.

4. Textile Finishing Equipment: Non-standard gearboxes are used in textile finishing equipment, such as stenter frames, calenders, and mercerizing machines. These gearboxes drive the rollers, pinning systems, and tension control mechanisms. They enable precise speed control, fabric spreading, and pressure adjustment, ensuring uniform and high-quality fabric finishing processes.

Chemical Industry:

1. Mixers and Agitators: Non-standard gearboxes find applications in mixers and agitators used in the chemical industry. These gearboxes drive the mixing blades, impellers, or paddles, providing the necessary torque and speed control for efficient blending, dispersing, and agitation of chemical substances.

2. Extruders: Non-standard gearboxes are employed in extruders used for plastic processing and rubber manufacturing. These gearboxes drive the screws or barrels, enabling precise control over the extrusion speed, pressure, and temperature. They ensure accurate material feeding, melting, and shaping processes in extrusion operations.

3. Pumping Systems: Non-standard gearboxes are used in pumping systems within the chemical industry. These gearboxes drive the pumps, providing the necessary power transmission and control for fluid movement and pressure generation. They enable precise flow rates, pressure control, and compatibility with specific chemical substances.

4. Reactors and Stirrers: Non-standard gearboxes find applications in reactors and stirrers used in chemical processing and pharmaceutical manufacturing. These gearboxes drive the stirring mechanisms, such as anchor stirrers or turbine stirrers. They provide controlled agitation, mixing, and heat transfer within reaction vessels, ensuring efficient chemical reactions and product quality.

5. Conveyors and Material Handling: Non-standard gearboxes are employed in conveyor systems and material handling equipment used in the chemical industry. These gearboxes drive the belts, chains, or rollers, enabling smooth and efficient transportation of bulk materials, granules, or containers within production facilities.

In each of these applications, non-standard gearboxes are customized and designed to meet the specific requirements of the textile equipment and chemical industry, including speed control, torque, durability, and compatibility with the respective processes. Collaborating with specialized gearbox manufacturers or engineering teams can help design and implement non-standard gearboxes that optimize the performance, reliability, and productivity in textile and chemical applications.

1BJY-324 4000LBS Capacity New Condition 12v Motor Trailer Electric Jack Parts and Accessories

1BJY-324 4000LBS Capacity New Condition 12v Motor Trailer Electric Jack Parts and Accessories 1BJY-HM-30 Chrome Ball Multi-Ball Mount New Condition Trailer Parts and Accessories with Clevis Hook Capacity 5000lbs

1BJY-HM-30 Chrome Ball Multi-Ball Mount New Condition Trailer Parts and Accessories with Clevis Hook Capacity 5000lbs 1BJY-A05 New Australian Coupler Equipped 3500KG Capacity Trailer Parts and Accessories with 50mm Ball Size

1BJY-A05 New Australian Coupler Equipped 3500KG Capacity Trailer Parts and Accessories with 50mm Ball Size Customized 40 Short Pitch Stainless Steel Extended Pin Roller Chain and Sprockets for Restaurant Industries

Customized 40 Short Pitch Stainless Steel Extended Pin Roller Chain and Sprockets for Restaurant Industries XG-4 High Quality Customized Rotary Tiller Blade Agricultural Machinery Part for Rotary Tiller Machine

XG-4 High Quality Customized Rotary Tiller Blade Agricultural Machinery Part for Rotary Tiller Machine 1BJY-TJ-15 New Weld-On Pipe-Mount Trailer Jack 5000LBS Capacity with Parts and Accessories Featuring Swivel Feature

1BJY-TJ-15 New Weld-On Pipe-Mount Trailer Jack 5000LBS Capacity with Parts and Accessories Featuring Swivel Feature