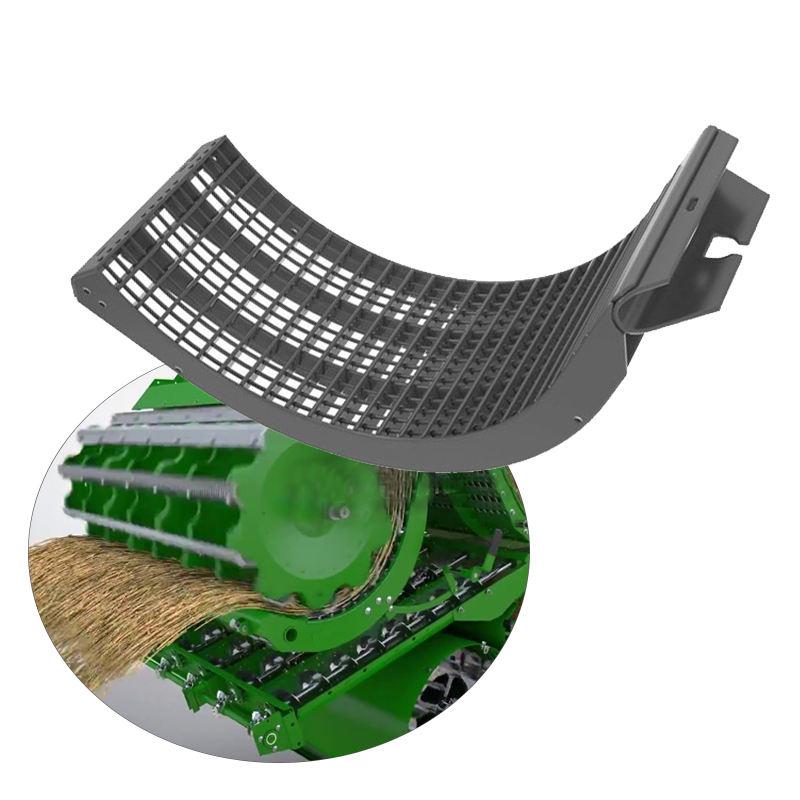

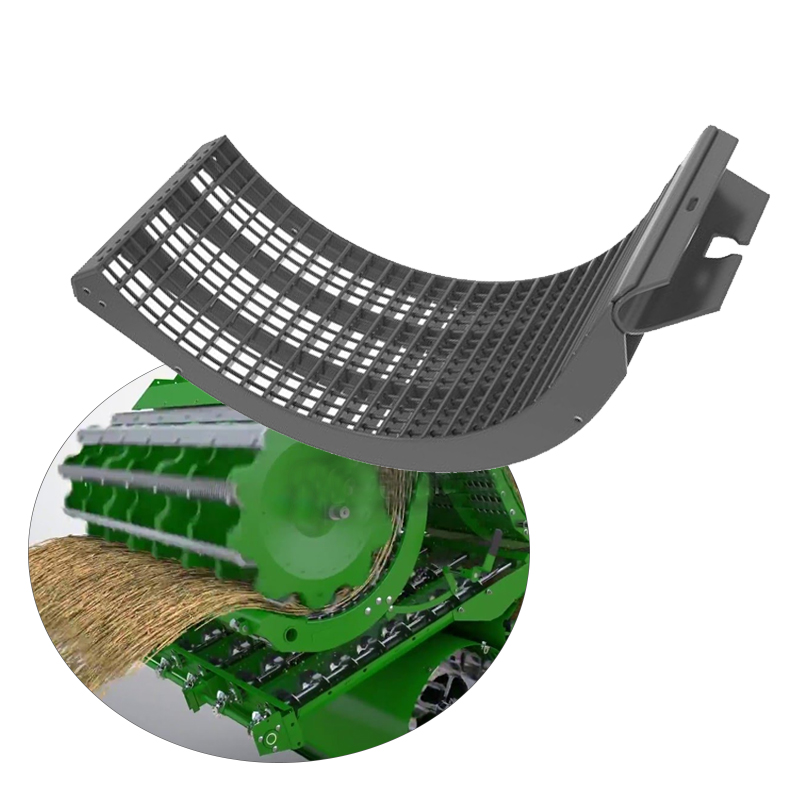

Our Concave uses industry-leading wear-resistant and corrosion-resistant materials, ensuring long-lasting durability and operational stability in harsh field operating environments. After precision casting and heat treatment, each Concave has high strength, toughness, and good fatigue resistance.

2.Precision design

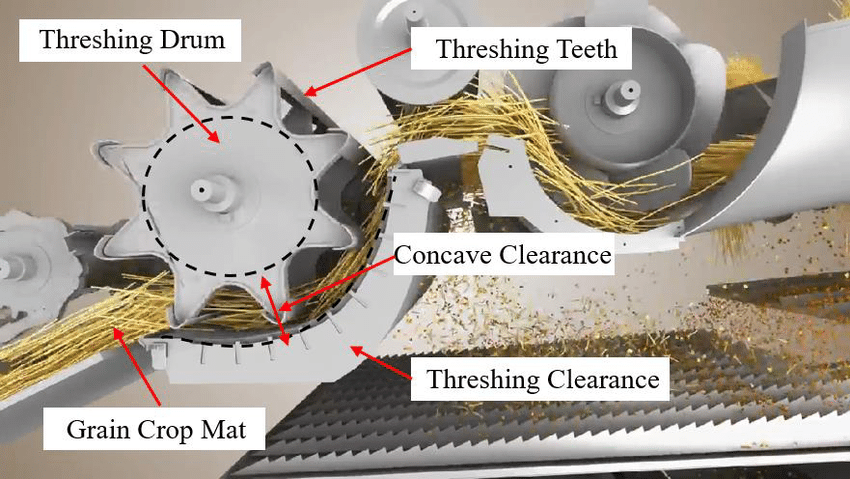

emphasizes customized design based on the characteristics of different crops, ensuring precise separation of grains and straw, and reducing loss rates.

3.Multiple Adaptations

List the brands and models of harvesters that can be adapted to meet the needs of different users.

1BJY-324 4000LBS Capacity New Condition 12v Motor Trailer Electric Jack Parts and Accessories

1BJY-324 4000LBS Capacity New Condition 12v Motor Trailer Electric Jack Parts and Accessories 1BJY-HM-30 Chrome Ball Multi-Ball Mount New Condition Trailer Parts and Accessories with Clevis Hook Capacity 5000lbs

1BJY-HM-30 Chrome Ball Multi-Ball Mount New Condition Trailer Parts and Accessories with Clevis Hook Capacity 5000lbs 1BJY-A05 New Australian Coupler Equipped 3500KG Capacity Trailer Parts and Accessories with 50mm Ball Size

1BJY-A05 New Australian Coupler Equipped 3500KG Capacity Trailer Parts and Accessories with 50mm Ball Size Customized 40 Short Pitch Stainless Steel Extended Pin Roller Chain and Sprockets for Restaurant Industries

Customized 40 Short Pitch Stainless Steel Extended Pin Roller Chain and Sprockets for Restaurant Industries XG-4 High Quality Customized Rotary Tiller Blade Agricultural Machinery Part for Rotary Tiller Machine

XG-4 High Quality Customized Rotary Tiller Blade Agricultural Machinery Part for Rotary Tiller Machine 1BJY-TJ-15 New Weld-On Pipe-Mount Trailer Jack 5000LBS Capacity with Parts and Accessories Featuring Swivel Feature

1BJY-TJ-15 New Weld-On Pipe-Mount Trailer Jack 5000LBS Capacity with Parts and Accessories Featuring Swivel Feature