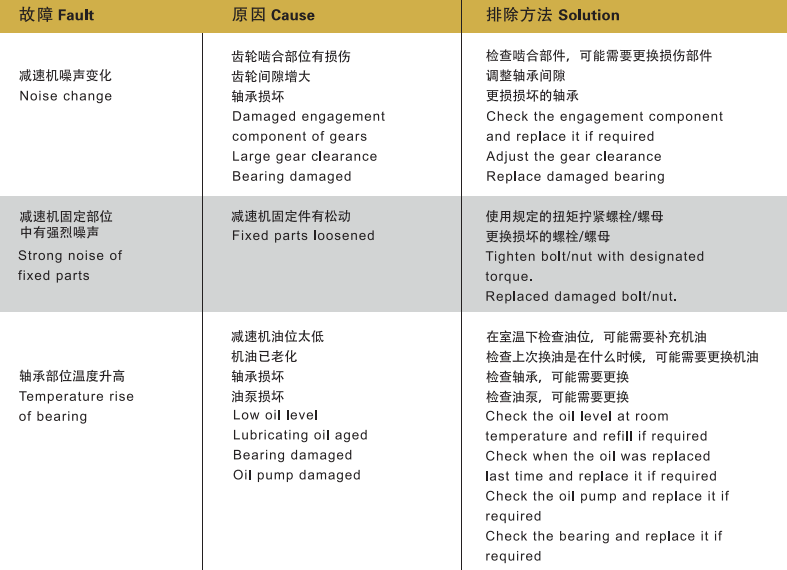

2. The reducer should be installed on a flat foundation. When the anchor screws are uniform and strong, the screw inserted into the output shaft can rotate evenly without jamming, so as not to add additional force to the output shaft and bearings and affect the bearing life. Strong assembly and disassembly of screws shall not be used.

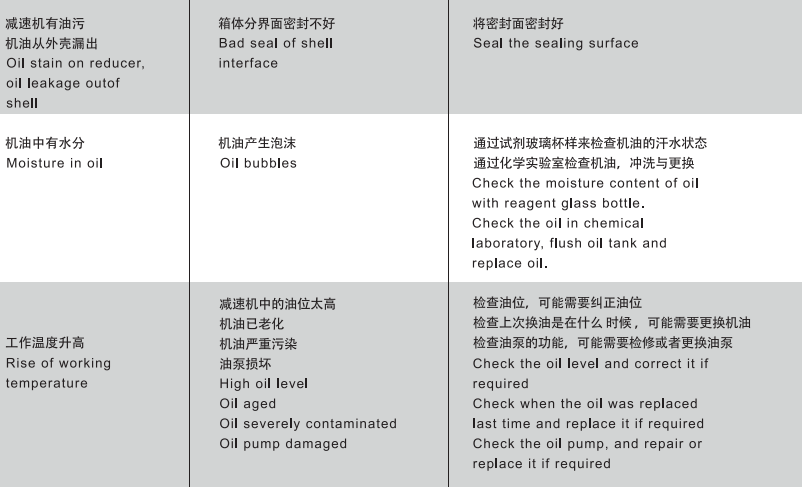

3. After the reducer is installed, add lubricating oil to the center line of the oil mark. The oil level should be determined after the lubricating oil is evenly distributed in the box, and the oil level should be checked frequently. Under any circumstances, the oil level should not be lower than the oil standard position. Please use medium-load industrial gear oil L-CKCC220 or L-CKC320. After the first use of 300 to 600 hours, the oil should be changed once. Change oil every 3000 hours. Replacement should be discharged when the reducer is stopped and the lubricant has not yet cooled. Rinse the box with oil of the same quality. If the viscosity is high, it is not suitable to rinse it. Heat it first or use a low viscosity oil.

4. A reducer equipped with forced lubrication of the oil pump may cause insufficient oil intake and excessive noise during the initial stage of driving due to excessive oil viscosity and large oil suction resistance of the oil pump. This phenomenon generally disappears after the lubricant oil temperature rises. The reducer with the motor oil pump should first turn on the motor oil pump before loading, and the empty car will run for a period of time to facilitate the sufficient lubrication of each lubrication point.

5. During normal operation, if the oil pump noise increases, the oil circuit may be too large. Please clean the filter and other related components in this situation. No matter which type of reducer is started when not used for a long time or when the temperature is too low, it should be run empty for a period of time and can only be loaded and operated after each bearing is fully lubricated.

6. When the oil temperature is found to rise significantly during work, when the temperature rises exceeds 70℃ or the oil temperature exceeds 100℃, the quality of the oil will drop, and abnormal noise will be generated. You should stop using it and check the reasons. If it is caused by tooth surface glueing, the fault must be repaired and eliminated, and the lubricant will be replaced before use.

1BJY-324 4000LBS Capacity New Condition 12v Motor Trailer Electric Jack Parts and Accessories

1BJY-324 4000LBS Capacity New Condition 12v Motor Trailer Electric Jack Parts and Accessories 1BJY-HM-30 Chrome Ball Multi-Ball Mount New Condition Trailer Parts and Accessories with Clevis Hook Capacity 5000lbs

1BJY-HM-30 Chrome Ball Multi-Ball Mount New Condition Trailer Parts and Accessories with Clevis Hook Capacity 5000lbs 1BJY-A05 New Australian Coupler Equipped 3500KG Capacity Trailer Parts and Accessories with 50mm Ball Size

1BJY-A05 New Australian Coupler Equipped 3500KG Capacity Trailer Parts and Accessories with 50mm Ball Size Customized 40 Short Pitch Stainless Steel Extended Pin Roller Chain and Sprockets for Restaurant Industries

Customized 40 Short Pitch Stainless Steel Extended Pin Roller Chain and Sprockets for Restaurant Industries XG-4 High Quality Customized Rotary Tiller Blade Agricultural Machinery Part for Rotary Tiller Machine

XG-4 High Quality Customized Rotary Tiller Blade Agricultural Machinery Part for Rotary Tiller Machine 1BJY-TJ-15 New Weld-On Pipe-Mount Trailer Jack 5000LBS Capacity with Parts and Accessories Featuring Swivel Feature

1BJY-TJ-15 New Weld-On Pipe-Mount Trailer Jack 5000LBS Capacity with Parts and Accessories Featuring Swivel Feature