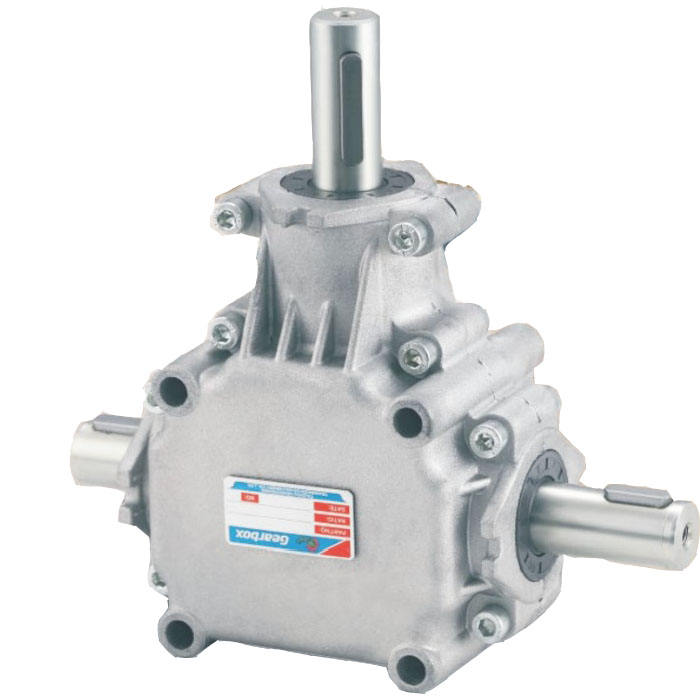

Characteristic

The 'W' transmission series is a good example of an Aluminum Box Series Gearbox. It has a die-casting aluminum housing, 2 taper roller bearings, and a full set of filler, level, and breather plugs. The main difference between the 'W' and the 'A' series is the design of the die-casting die. A die-casting die is designed with the optimum amount of friction, heat, and stress relief, as well as a complete seal.

Featured in Toyota's 'W' transmission family

A family of RWD/4WD transmissions, the W series is built by Aisin and shared a bell housing to body bolt pattern. They are all 4-speeds and shared gear ratios. The W45 was a 4-speed variant of the W55 that was used in Toyota RWD cars from around 1980. While the case is aluminum, this transmission still uses the same mount. Several variations of the W55 were made.The W57 and W58 are based on the same basic design but have different gear ratios. The W57 and W58 have lower ratios, allowing them to accelerate faster even when their base ratios are similar. Both the W57 and W58 have the same base ratios but differ in the 5th gear. The W57 is often referred to as a close-ratio box, but that doesn't mean that it matches the W58's close-ratio characteristics.

Made with die-casting aluminium housing

Die-casting is an economical method to produce large quantities of aluminum components. Aside from its cost-effectiveness,die-casting also produces parts with complex 3D shapes. For this purpose, aluminum alloys are best suited. Many industries use die-casting to make heating plates because it is less costly and more convenient. This method can create custom-made parts that require no additional machining. Aside from being cost-effective, die-casting also produces high-quality parts that last for many years.

The quality of die-casting aluminum parts and housings is excellent. These parts can withstand high-pressure and temperature conditions, allowing them to withstand a variety of applications. They are also extremely lightweight. This makes them ideal for lightweight, outdoor applications. In addition, they are resistant to corrosion and environmental factors. This is the reason why many automobile manufacturers prefer this material for their parts. The benefits of die-casting aluminum are numerous.

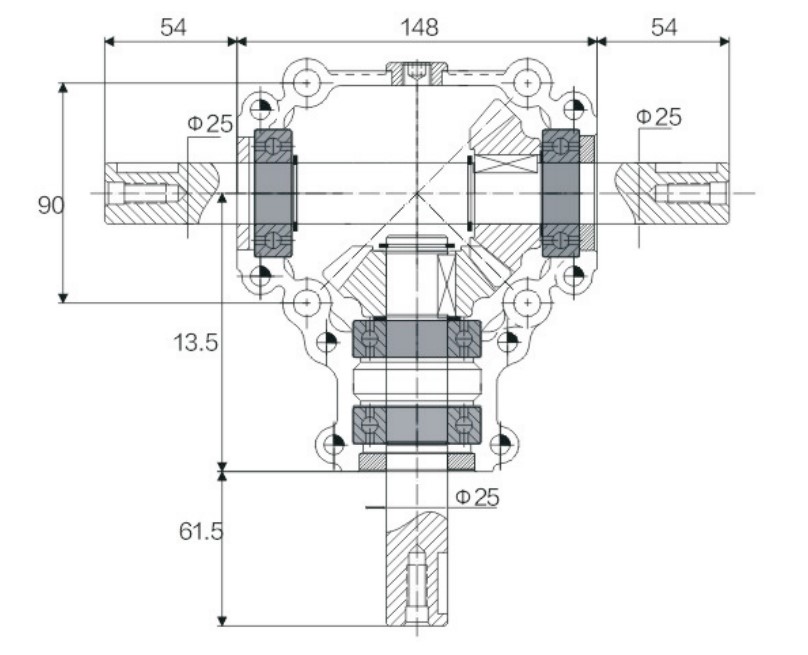

Equipped with 2 taper roller bearings

Increasingly, equipment that is equipped with two taper roller bearings is being used. The difference between the two types of tapered bearings is the finished spacer width. Finished spacer width controls the mounted setting for the bearings. Depending on the application, the bearing may be mounted with either an axial or a radial force. This feature allows it to operate without a tight shaft fit.

The tapered roller bearings are unique from other types of bearing cages. Pin cages are the most common type. One ring is welded to the end of each roller, while the other ring has a series of pins around the circumference. The cage is usually polymer. Higher numbers of rollers mean a higher load capacity, but a greater number of rollers also reduces a bearing's capability under high speed, dynamic loads, and vibration.

Designed with a full set of filler, level and breather plugs

The "BOX" series worm gear units feature die-cast aluminium housing in sizes 25 to 90 and cast iron in sizes 110 and up. These units feature a two-row gearbox with 2RS autolubricated bearings on the output gear. The housings are designed with a full set of filler, level, and breather plugs for all mounting positions. In addition, they are equipped with special RS shields to facilitate easy mounting in positions V5 and VI without any extra interventions.

*Gears and shafts are quenched and have high surface hardness.

*Use high-quality oil seals and bearings.

*Each gearbox can be delivered after passing the inspection.

*The gearbox has low noise, and stable operation and is made of nodular cast iron with strong toughness and long service life.

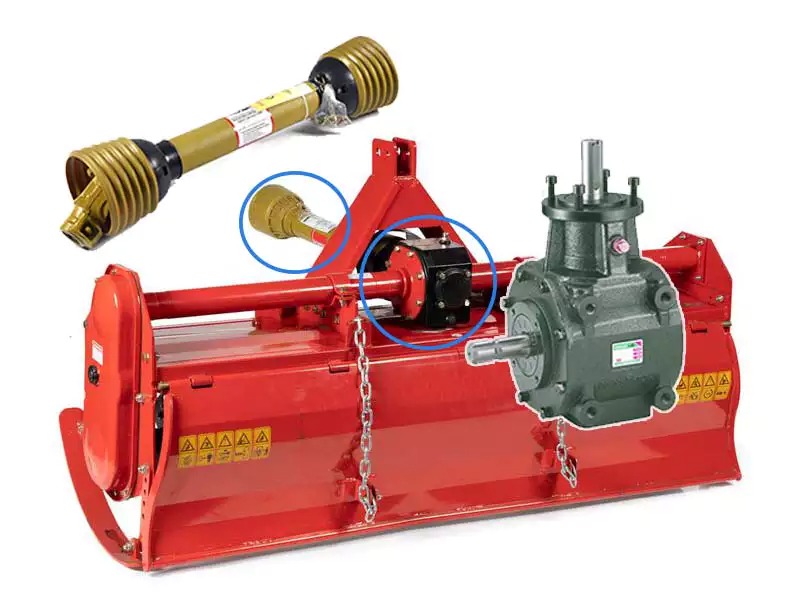

Agricultural Gearbox for Flail Mower PTO Drive Shaft Steel Straight Spline Drive Gear High Precision OEM

Agricultural Gearbox for Flail Mower PTO Drive Shaft Steel Straight Spline Drive Gear High Precision OEM Multifunctional Agricultural Lawn Mower Series Gearbox

Multifunctional Agricultural Lawn Mower Series Gearbox Omni Series Rc 61 Drive Pto Agricultural Farm Heavy Duty Shredders Slasher Lawn Mower Rotary Cutter Gearbox for Bush Hog

Omni Series Rc 61 Drive Pto Agricultural Farm Heavy Duty Shredders Slasher Lawn Mower Rotary Cutter Gearbox for Bush Hog Agricultural Lawn Mower Series Gearbox with Low Price

Agricultural Lawn Mower Series Gearbox with Low Price New Design Agricultural Rotary Cultivator Series Gearbox with Great Price

New Design Agricultural Rotary Cultivator Series Gearbox with Great Price Plastic Agricultural Aluminum Box Series Gearbox Made in China

Plastic Agricultural Aluminum Box Series Gearbox Made in China