Characteristic

Designed for heavy-duty industrial applications, the Gearbox Aluminum Box Series is the ideal choice for a wide variety of

industries. Its low maintenance, strong structure, and long service life make it an ideal choice for a wide variety of

applications. Learn how these gearboxes work in the industries below. Weighing just a few pounds, these gearboxes are extremely durable and low-maintenance.

Gearboxes are used in many industries

Besides being an important element of machinery, gearboxes are also used in many other industries. These units are used to increase torque, and in some cases, to reduce speed. They come in a variety of types, and can also be custom-built to meet specific requirements. The paper industry, for example, relies heavily on industrial machinery, including custom-built gearboxes. The following are some of the industries that use gearboxes:

Automobile gearboxes are manufactured from aluminum alloy. The aluminum alloy used for gearboxes is known to have a high strength-to-weight ratio. It also has excellent corrosion, wear and thermal conductivity properties. The main advantages of aluminum alloy gearboxes are their high strength-to-weight ratio, low density, good thermal conductivity and attractive appearance. For the manufacturing of gearboxes, these alloys are usually die-cast or mechanically processed.

They are low maintenance

The benefits of the Gearbox Aluminum Box Series are the reduced wear and tear and high durability of this aluminum gearbox. These gears feature helical bevel gear design and are lightweight and durable. The gears also feature synthetic oil lubrication for long life. The Ket-Motion 2020 miter gear is designed for high-speed and low-noise transmission operations. The high-precision design of this gearbox provides nine reductions per tooth and features a high-strength aluminum alloy housing.

They are strong

The Gearbox Aluminum Box Series are designed and manufactured using high-strength aluminum alloys. The structure of these gearboxes is complex, with concave and convex structures and a side core-pulling mechanism. The main component of this alloy is AlSi9Cu3 for high-strength aluminum alloy gearbox housings. The chemical composition and mechanical properties of these gearboxes are also of the highest quality. High-pressure point cooling inserts were set on a slide block or side slider to increase the speed of cooling the position.

They have a long service life

The Superior Gearbox Company right angle gear drives offer efficiency, quiet operation, and long service life. Available in a

variety of materials, inch sizes, and custom designs, these units offer long-lasting protection and high reliability. They are

especially suitable for use in extreme temperatures. For more information, please see the product pages of the Superior Gearbox Company. We are also able to provide a free quotation for any gearbox solution you may require.

High operating temperatures contribute to shorter service life and premature gearbox failure. High operating temperatures also contribute to excessive noise and vibration levels, affecting employee safety. Additionally, extreme cooling tower conditions degrade the mechanical systems and reduce gear set life. Premature bearing failure causes excessive wear and tear on the pinion shaft. In addition, few cooling tower gearboxes are designed to support scheduled maintenance, reducing motor size and fan performance while maintaining structural integrity.

They are able to withstand high shock loads

Gearboxes are critical components of many mechanical systems. High shock loads can be a huge problem for standard off-the-shelf gears. However, new designs are constantly being developed, and many of them now have features that are beneficial for high-shock-load applications. A Gearbox Aluminum Box Series, for example, can withstand shock loads of up to five tons.The aluminum alloy used in the Gearbox Aluminum Box Series allows the gearbox to withstand shocks and high temperatures. Different heat treatment processes impart different characteristics to gears. In addition, heat treatment of gears can reduce distortion and the overall cost of gear manufacturing. This is important for minimizing manufacturing costs. Gears that are hardened are also less likely to fail prematurely. With this design, the Gearbox Aluminum Box Series is able to withstand high shock loads, and they can be used for a variety of applications.

*Gears and shafts are quenched and have high surface hardness.

*Use high-quality oil seals and bearings.

*Each gearbox can be delivered after passing the inspection.

*The gearbox has low noise, and stable operation and is made of nodular cast iron with strong toughness and long service life.

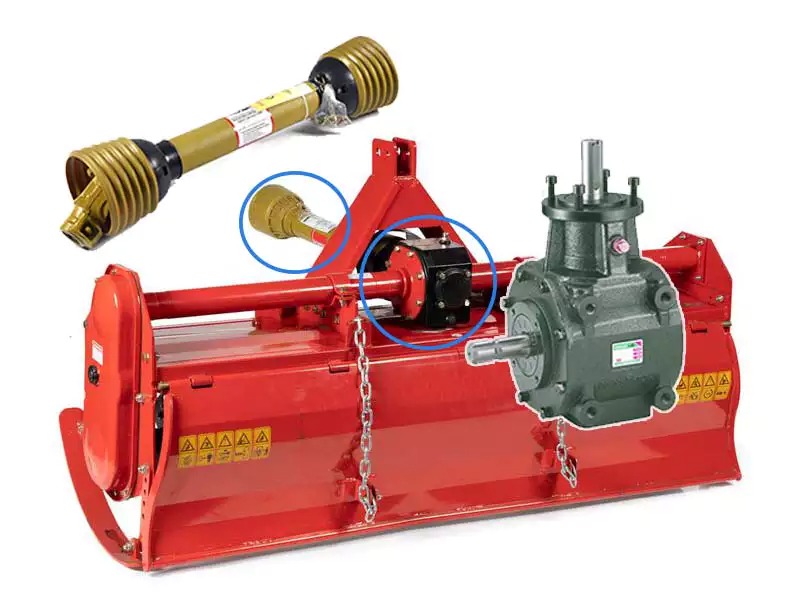

Agricultural Gearbox for Flail Mower PTO Drive Shaft Steel Straight Spline Drive Gear High Precision OEM

Agricultural Gearbox for Flail Mower PTO Drive Shaft Steel Straight Spline Drive Gear High Precision OEM Multifunctional Agricultural Lawn Mower Series Gearbox

Multifunctional Agricultural Lawn Mower Series Gearbox Omni Series Rc 61 Drive Pto Agricultural Farm Heavy Duty Shredders Slasher Lawn Mower Rotary Cutter Gearbox for Bush Hog

Omni Series Rc 61 Drive Pto Agricultural Farm Heavy Duty Shredders Slasher Lawn Mower Rotary Cutter Gearbox for Bush Hog Agricultural Lawn Mower Series Gearbox with Low Price

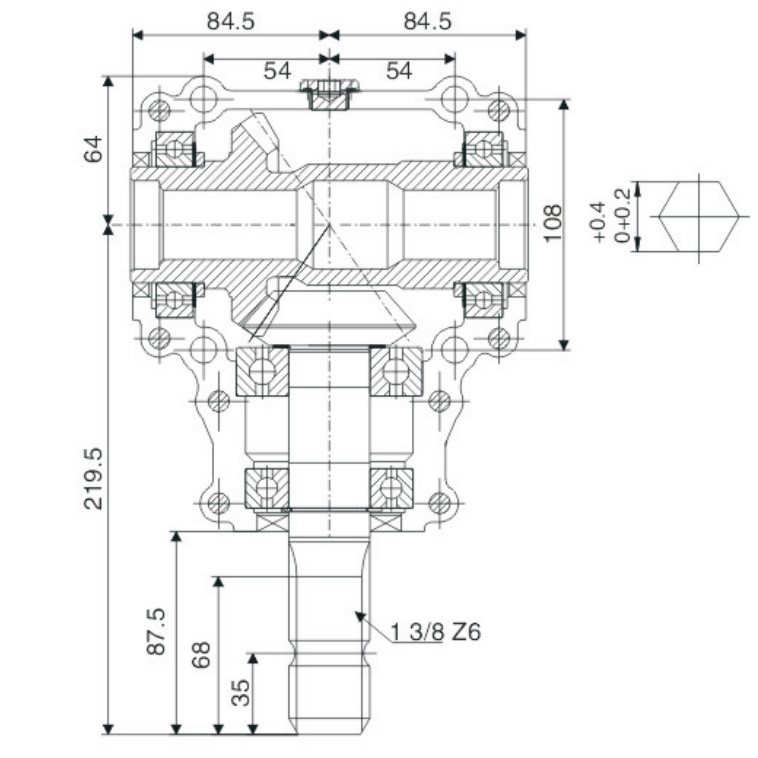

Agricultural Lawn Mower Series Gearbox with Low Price New Design Agricultural Rotary Cultivator Series Gearbox with Great Price

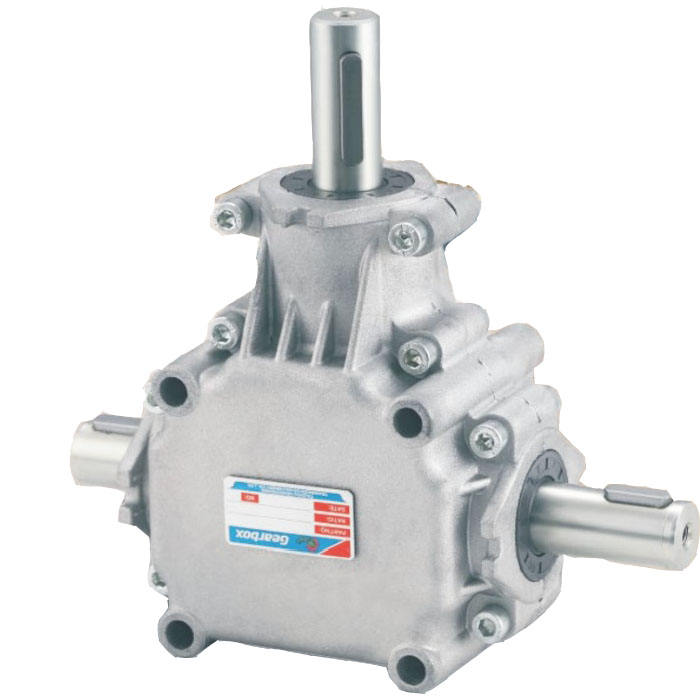

New Design Agricultural Rotary Cultivator Series Gearbox with Great Price Hot Selling Agricultural Aluminum Box Series Gearbox with Low Price

Hot Selling Agricultural Aluminum Box Series Gearbox with Low Price